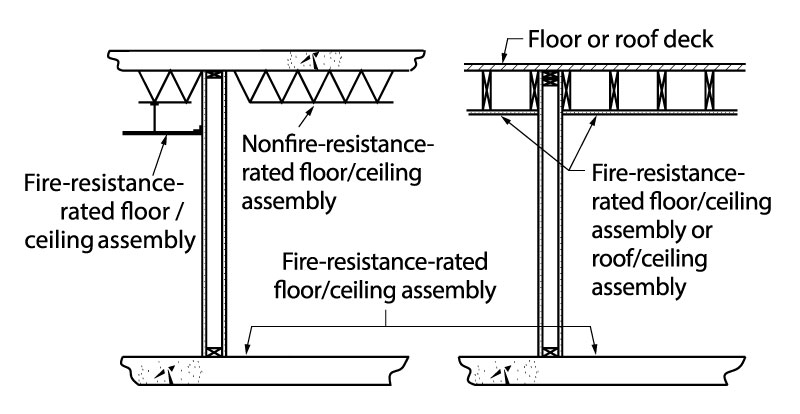

A minimum 1 hour fire resistance rating to prevent embers and hot gases from making contact with the joists rafters or trusses or the underside of the roof decking.

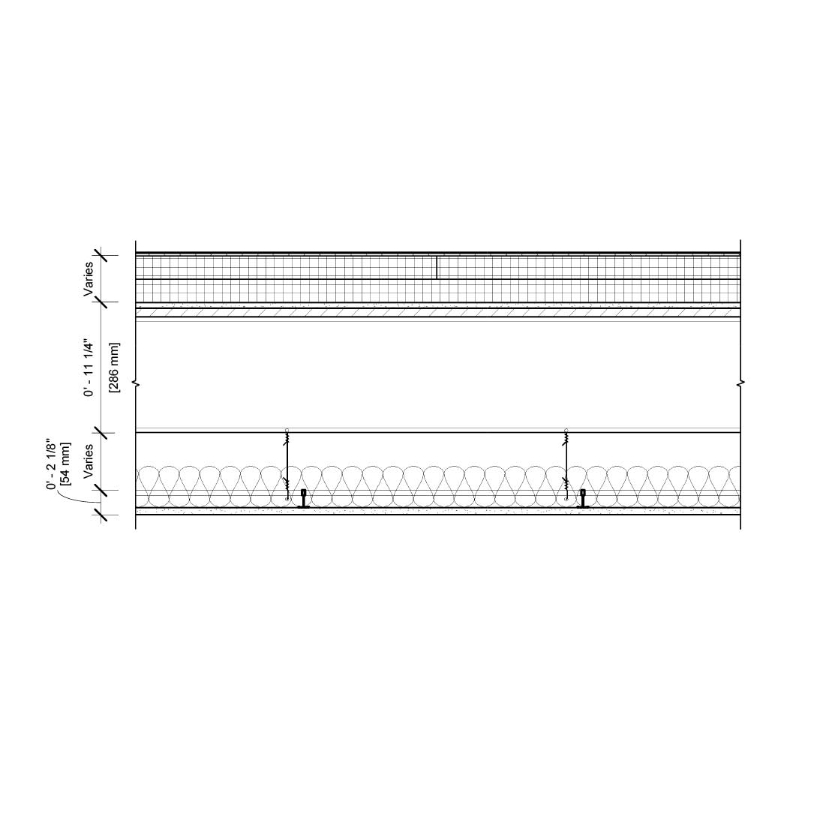

1 hour rated roof assembly residential.

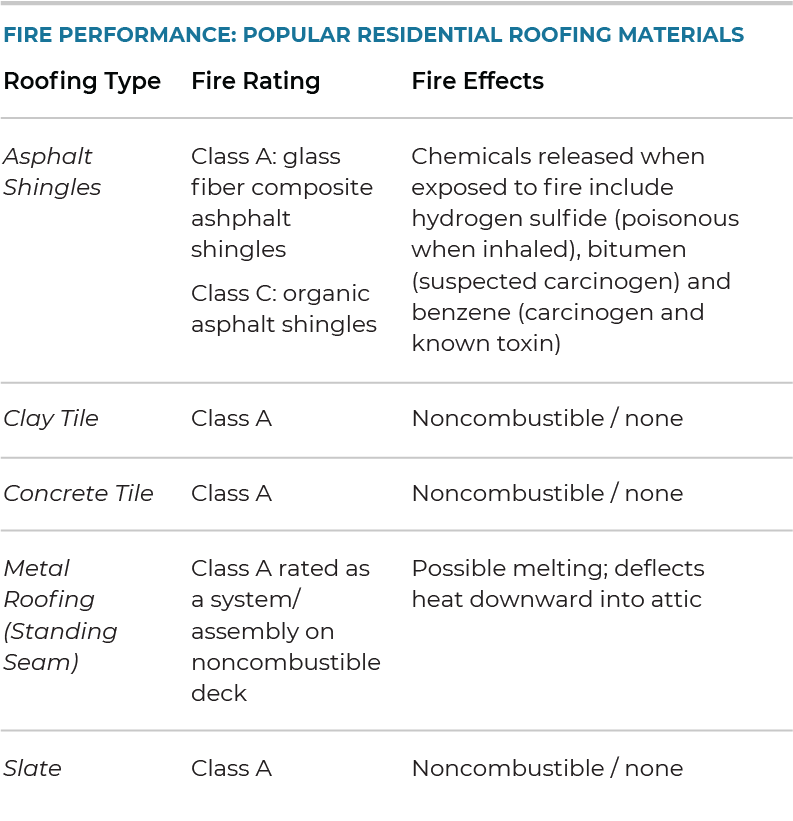

For example shake roofing with a fire retardant treatment rates class b on its own but achieves a class a rating when combined with specified underlying materials such as type 72 roll roofing material.

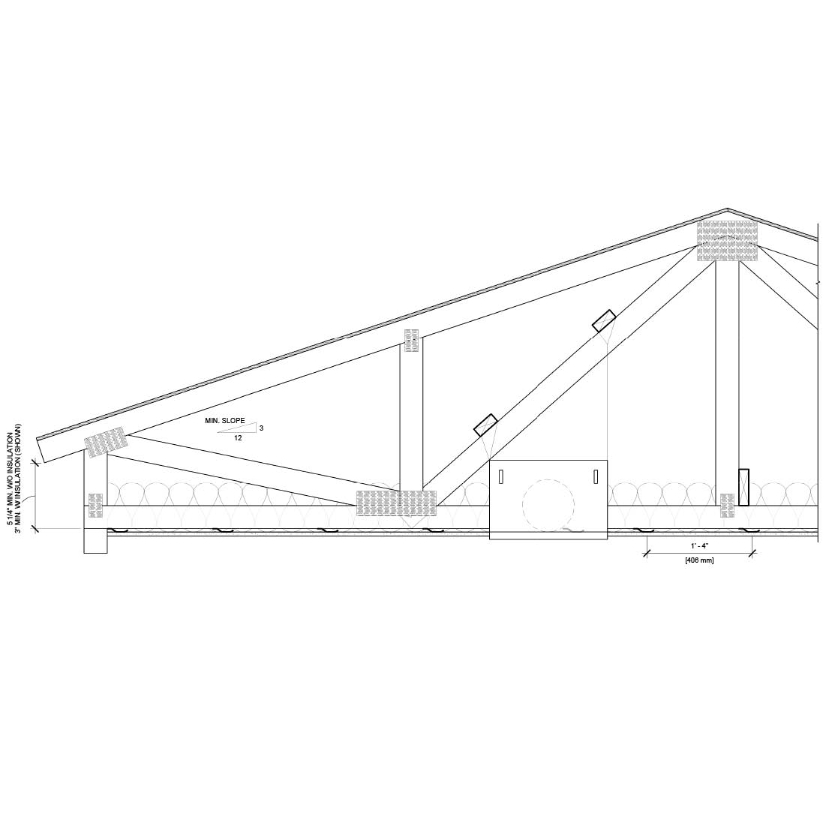

Use flat horizontal soffits see figure 3 instead of attaching the soffits to the sloped joists which creates sloped soffits.

2 hour exterior wall assembly ul design no.

Assembly rated class a roof coverings are those that meet class a standards when combined with other elements.

Long cup head drywall nails 8 in.

Face layer 5 8 in.

No minimum joist size is given except that it needs to be adequate for structural loads.

Ibc table 722 6 2 2 allows 10 minutes for wood floor or roof joists at 16 o c.

Ul does not appear to list an assembly as described.

Usg provides resources here for our ul wall assemblies for seamless integration into any construction project.

I am looking for a 1 hour roof ceiling assembly for wood truss construction.

1 hour exterior wall assembly ul design no.

These wall assembly files are used for planning and estimation purposes for many ul wall types such as fire rated wall assemblies.

6 usg fire resistant assemblies test certification test conditions and fire and sound tested assemblies listed in this selector are based on characteristics properties and performance certificationof materials and systems obtained under controlled test conditions as set forth in the appropriate astm standard in effect at the time of test.

These listings are short summaries to serve as a.

Is this possible without using channels and what ul number would i use.

I would like to apply the drywall directly to the bottom of the truss and also have insulation for sound control.

Type x gypsum wallboard applied vertically fastened with 1 7 8 in.

Thick x 4 ft.

Rated from one side and from both sides.

Gypsum panel end joints located midway between continuous channels and attached to additional pieces of channels 54 1372 mm long with screws 12 305 mm o c.

Lp flameblock fire rated osb sheathing is a component of the following code compliant fire rated assemblies.

Joint tape and compound vinyl or casein dry or premixed joint compound applied to face.

With 1 25 mm type s drywall screws 12 305 mm o c.

1 hour wall assembly interek design no.

1 2 12 7 mm toughrock fireguard c or 1 2 12 7 mm densarmor plus fireguard c gypsum panel applied perpendicular to resilient channels 24 610 mm o c.